Recognised, wanted and appreciated for four generations, the expertise of Pappos Shoes workshop reunites several arts and crafts. Each requires patience, control and experience nurtured over time. Our experience enables us to follow, step by step, the creation of an exceptional shoe.

The Process

The Know How

The Last Maker

After taking the measurements, the last maker writes all the necessary aesthetic information to make the wooden last, which will be used as the base for the shoe creation. It usually takes between four and six hours to sculpt. The last maker then designs the insole (the part which will be under the last during the assembly of the shoe) and heel.Once the order is delivered, it will join the Pappos archives, rich with hundreds of pairs of lasts, all scratched with the name of their owners.

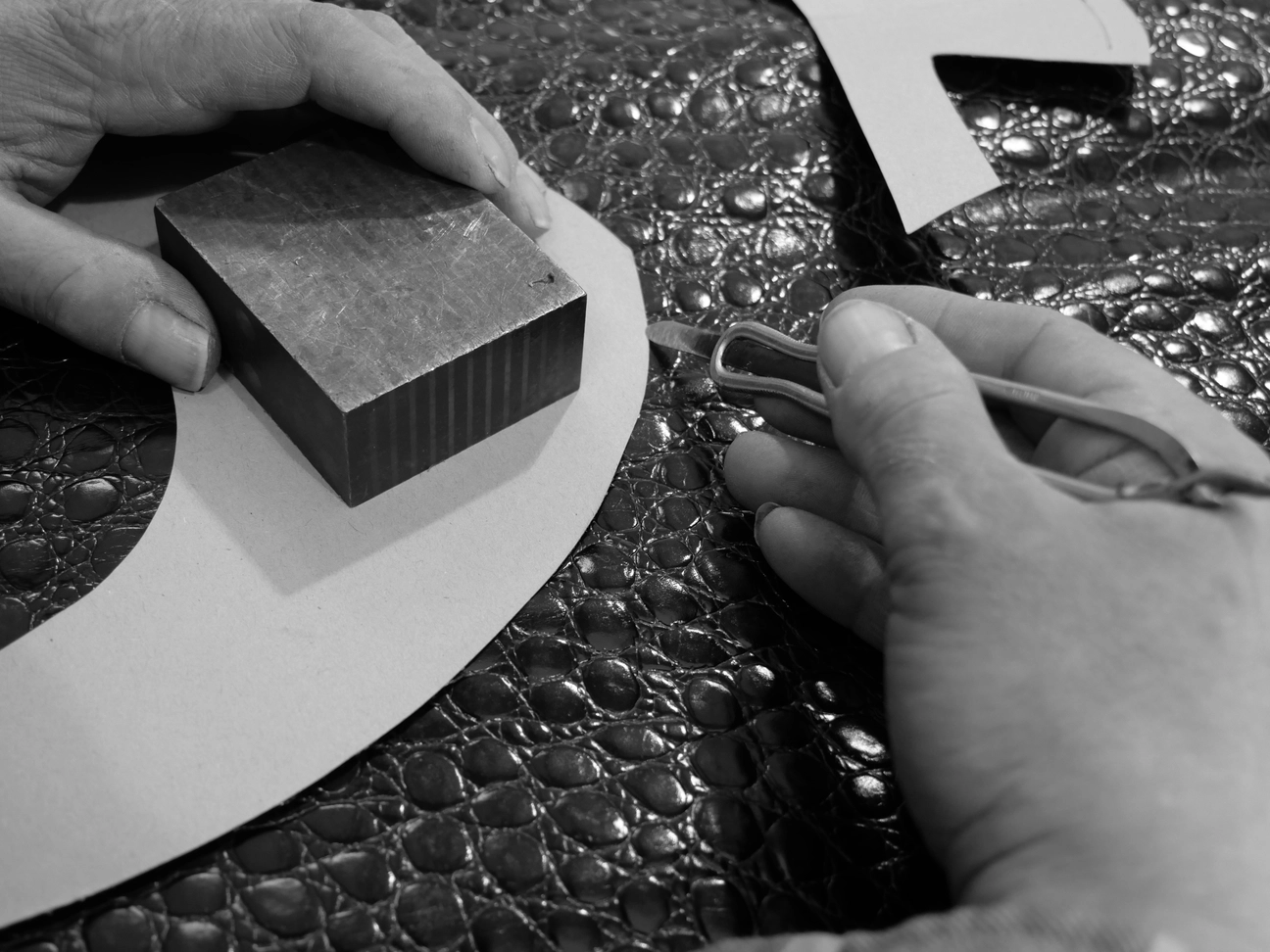

The Clicker

The Clicker is in charge of drawing the pattern on the last sculpted by the last-maker. The clickers’ work must be very precise and meet certain proportions, vamp and quarter height to stick as close as possible to the sketch.

The Closer

From the pattern drawn by the Clicker, the Closer assembles the cut skin parts and builds the upper part of the shoe.

The Assembler

The Assembler shapes the interior components and marries the upper part of the shoe and the insole. This step requires great delicacy and a meticulous hand: curved and stretched over the last, the upper part of the shoe should perfectly match the lines of the last to give birth to an impeccably fitted shoe.

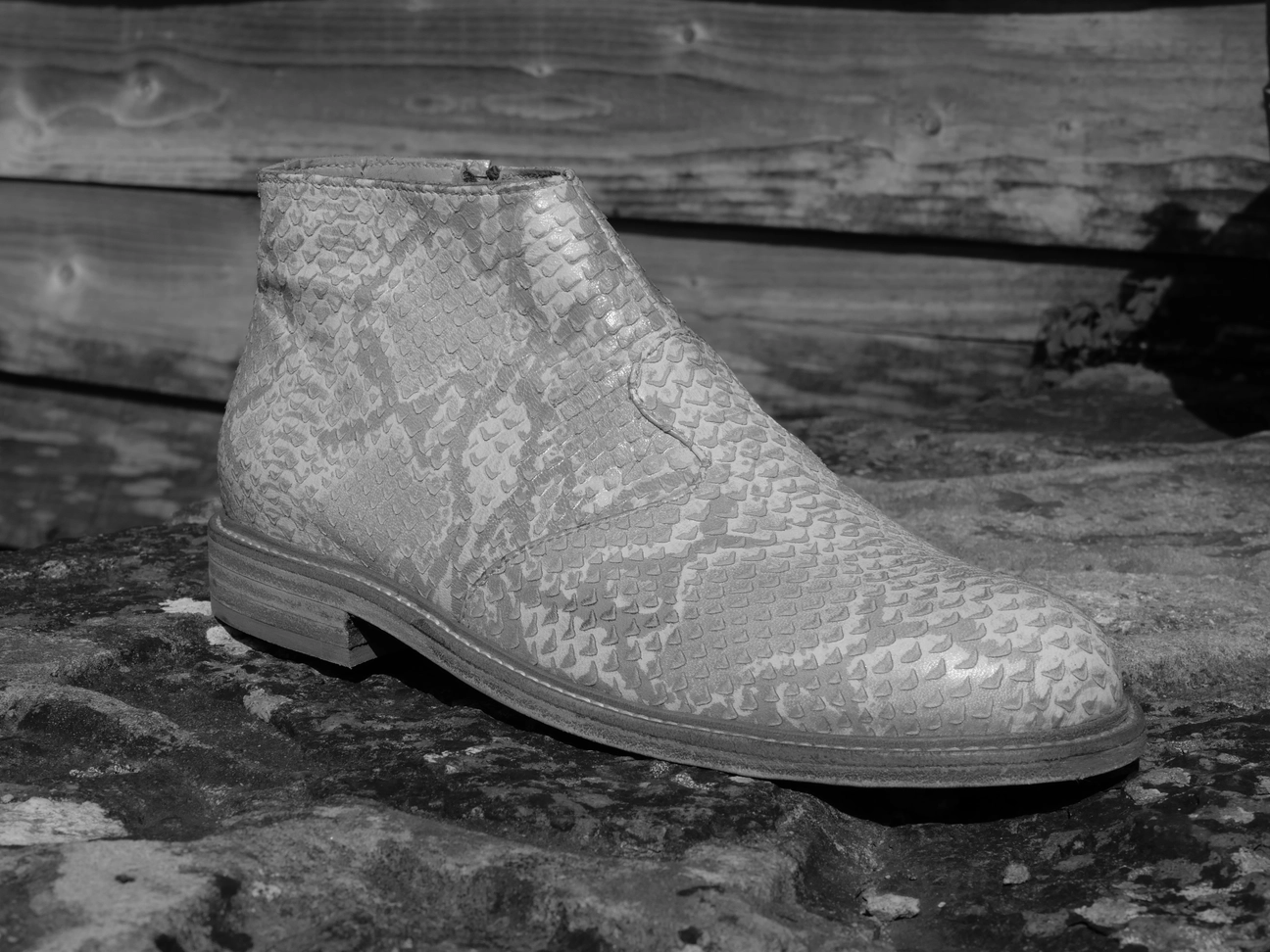

The Finisher

A good clean, a perfected polish and a patina. No thread or lining will escape the Finisher’s careful eye. Now the shoe is ready to be delivered. Thirty hours at least are necessary to give birth to a pair of pumps. And it takes nearly fifty for a pair of men’s shoes.